Digital Twin-Enabled Adaptive Fleet Management

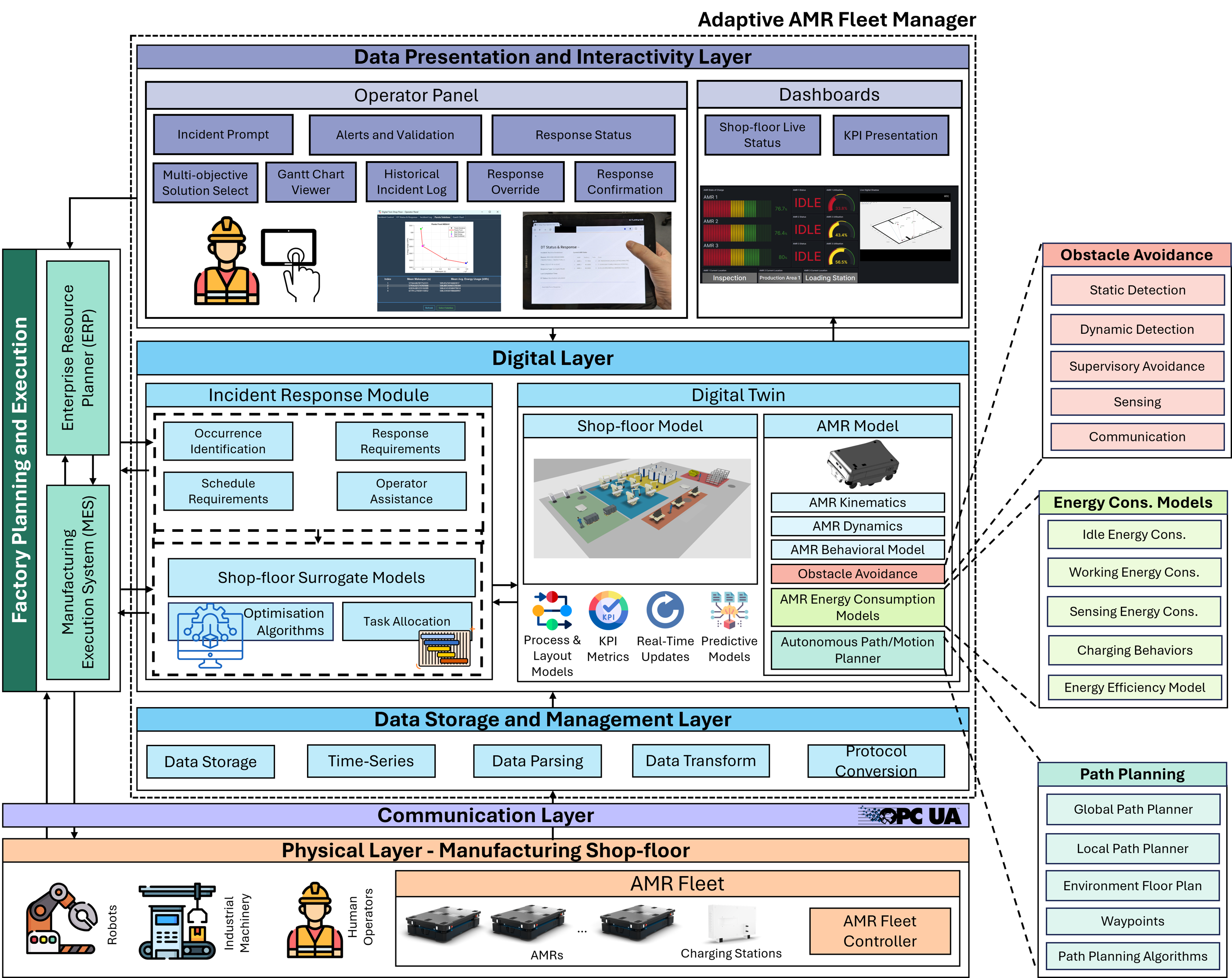

Developing a human-centred, resilient Digital Twin framework that enables real-time incident-aware scheduling, operator-guided decision making, and robust Autonomous Mobile Robot fleet coordination in smart manufacturing environments.

Overview

This project introduces a human-centred Digital Twin framework that integrates multi-fidelity models, surrogate optimisation, and high-fidelity simulation to support resilient AMR fleet management in dynamic smart factories. It detects operational disruptions such as robot failures or machine breakdowns and rapidly generates incident-aware schedules while preserving throughput and energy efficiency. A human-in-the-loop decision layer allows operators to review trade-offs, request re-simulation and apply policy-bound overrides, ensuring transparency, governance and Industry 5.0–ready coordination.